Pradiareň 1900 - History and interesting facts

Pradiareň was founded in 1900 by Salcher & Richter and J. & P. Coats. It was designed by Viennese architects D. V. Junk and K. K. Baurath. The name Zwirn is based on the original name, Uhorská cvernová factory (Zwirnfabrik, Magyer czérnagyár), and its construction took place in several stages. Learn more about how precious this national cultural monument is.

Pradiareň 1900Pradiareň 1900

In 1902, the southern part of Pradiareň was built along with the adjoining Silocentrála building, which served as the energy center for the entire complex. Around 1905, the successful production results of the Uhorská cvernová factory led to an expansion of the original building with the completion of the northern part. The most modern machines, state-of-the-art technologies, and the resulting products, which went to various parts of the monarchy and abroad, became the decisive reason for the addition of the third floor to Pradiareň in 1912. The problem of having a lack of technological means for transporting material in the building was solved in 1920 by adding three freight elevator shafts to the eastern facade. At the threshold of the 20th century, the building represented the pinnacle of artistic and structural architecture of the period. The building modifications in the second half of the 20th century were only utilitarian, which had a rather negative effect on the quality of the original architecture.

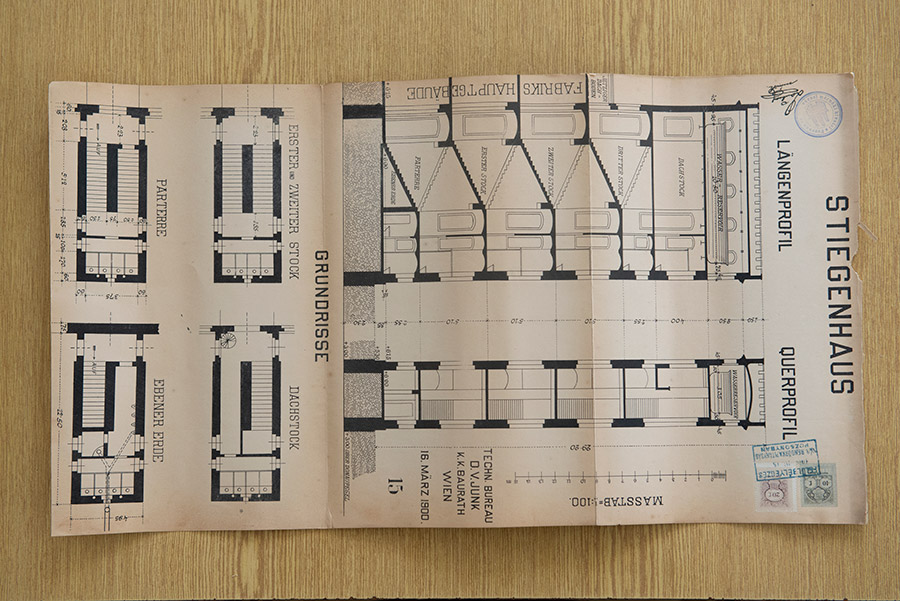

Project of staircase, one of the oldest part of the building, 1900

Cooling towers near Silocentrála building, 1912

Creative studiosCreative studios

Beginning in the year 2000, after the end of production, the building was transformed into a creative and exhibition space, and it was home to creative studios.

In 2006 and 2007, painters, photographers, architects, filmmakers, and designers gradually took over the premises of the former Pradiareň factory. It housed more than 30 studios. Instead of threads, the factory began producing pieces that could be admired by the world at Tate Modern in London, visitors to the Venice Biennale, and at many other world-class shows and markets. It suddenly became one of the first creative community centers despite the lack of interest of the municipality and investors. At the same time, four members of the creative community initiated the establishment of the Cvernovka Foundation in order to enhance the cultural, social, and material value of the former industrial area of the factory. Gradually, its closed community began to be more open to the public when various community civic associations, a bookstore, a coworking center, and a gallery set up shop there. After negotiations with the investor in 2016, the creative community left the building and moved to new premises on the site of a former chemical manufacturer.

-

![Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community]()

Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community

-

![Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community]()

Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community

-

![Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community]()

Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community

-

![Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community]()

Priestory Pradiarne počas fungovania kreatívnej komunity / Pradiareň during the operation of the creative community

The windows of PradiareňThe windows of Pradiareň

Throughout Pradiareň you will find a total of 505 windows in 78 shape variations. The windows on the ground floor were uncovered during the reconstruction of the building and were restored and reinserted.

80 windows underwent refurbishment and were reinserted. The remaining 425 windows copy the original design from 1900. The windows were originally round, but were later changed to a square shape when the facade was repaired. During the revitalization from 2018 to 2020, the investor preserved some of the windows, restored them, and changed them back to their original round appearance. The rest of the windows are new and aluminum with insulating double glazing and a metal coating to protect against sunlight. They were made based on the original design from 1920.

-

![Okná Pradiarne z exteriéru po necitlivej prestavbe v polovici 20. storočia / Pradiareň windows after an insensitive reconstruction in the mid 20th century]()

Okná Pradiarne z exteriéru po necitlivej prestavbe v polovici 20. storočia / Pradiareň windows after an insensitive reconstruction in the mid 20th century

-

![Okno Silocentrály / Winow of Silocentrála]()

Okno Silocentrály / Winow of Silocentrála

-

![Pôvodné zamurované okno / An original bricked up window]()

Pôvodné zamurované okno / An original bricked up window

-

![Okna Pradiarne z interiéru počas rokov stratili svoj pôvodný tvar / Windows had lost its original shape]()

Okna Pradiarne z interiéru počas rokov stratili svoj pôvodný tvar / Windows had lost its original shape

-

![Zamurované okno na schodisku Silocentrály / Bricked up stairway window in Silocentrála]()

Zamurované okno na schodisku Silocentrály / Bricked up stairway window in Silocentrála

Reconstruction of PradiareňReconstruction of Pradiareň

Thanks to a sensitive reconstruction process, the original art deco decoration on the columns on the ground floor of Pradiareň was partially restored. The use of artistic elements in architecture is a characteristic feature of industrial buildings from the early 20th century.

Other significant historical elements include preserved and restored steel windows, with their typical multiple panes of glass and inventive opening system, as well as cast-iron columns and an Art Nouveau steel spiral staircase. The restored exterior of Pradiareň is characterized by a white facade with window panels in the original green color. The original architectural elements, arched window openings and the historic shape of the attic, were restored on the facade. Significant new design elements are the steel columns in Silocentrála, the steel entrance portals, and the new reinforced concrete staircase in the connecting passage of Silocentrála. The original combination of coarse-grained plaster and brick masonry work from 1902 is preserved on the building of Silocentrála. New entrances and window openings on the northern and eastern facades that are characteristically framed by sheets of steel are significant architectural elements. This national cultural monument has undergone a demanding reconstruction under the direction of the BOUDA MASÁR architectural studio. Despite all the necessary adaptations to allow for new functions in the building, its final form really lets the period architecture and the structural craft stand out.

-

![Budova Pradiarne tesne pred rekonštrukciou / Soon to be reconstructed Pradiareň]()

Budova Pradiarne tesne pred rekonštrukciou / Soon to be reconstructed Pradiareň

-

![Pradiareň a Silocentrála pred rekonštrukciou / Pradiareň and Silocentrála before the reconstruction]()

Pradiareň a Silocentrála pred rekonštrukciou / Pradiareň and Silocentrála before the reconstruction

-

![Liatinové schodisko pred obnovou, nachádza sa v budove Silocentrály / Cast iron staircase and railing in Silocentrála building]()

Liatinové schodisko pred obnovou, nachádza sa v budove Silocentrály / Cast iron staircase and railing in Silocentrála building

-

![Traverzové klenby s betónovou výplňou a vzácne liatinové stĺpy / Traverse vaults with concrete filling]()

Traverzové klenby s betónovou výplňou a vzácne liatinové stĺpy / Traverse vaults with concrete filling

-

![Vrchá časť vzácneho liatinového stĺpu s prstencovou hlavicou / Top part of precious cast iron column]()

Vrchá časť vzácneho liatinového stĺpu s prstencovou hlavicou / Top part of precious cast iron column

-

![Liatinová podložka priečnych tiahel]()

Liatinová podložka priečnych tiahel

-

![Na niektorých liatinových stĺpoch sa našla art-deco výzdoba, ktorá bola obnovená v priestoroch lobby - Some of the cast iron columns have its original art deco finishing]()

Na niektorých liatinových stĺpoch sa našla art-deco výzdoba, ktorá bola obnovená v priestoroch lobby - Some of the cast iron columns have its original art deco finishing

-

![Liatinový stĺp vyrobený v Budapešti firmou Waagner / Cast iron column built by Budapest company Waagner]()

Liatinový stĺp vyrobený v Budapešti firmou Waagner / Cast iron column built by Budapest company Waagner

-

![Nosné liatinové stĺpy vyrobené v Budapešti firmou Schlick / Cast iron columns built by Budapest company Schlick]()

Nosné liatinové stĺpy vyrobené v Budapešti firmou Schlick / Cast iron columns built by Budapest company Schlick

SilocentrálaSilocentrála

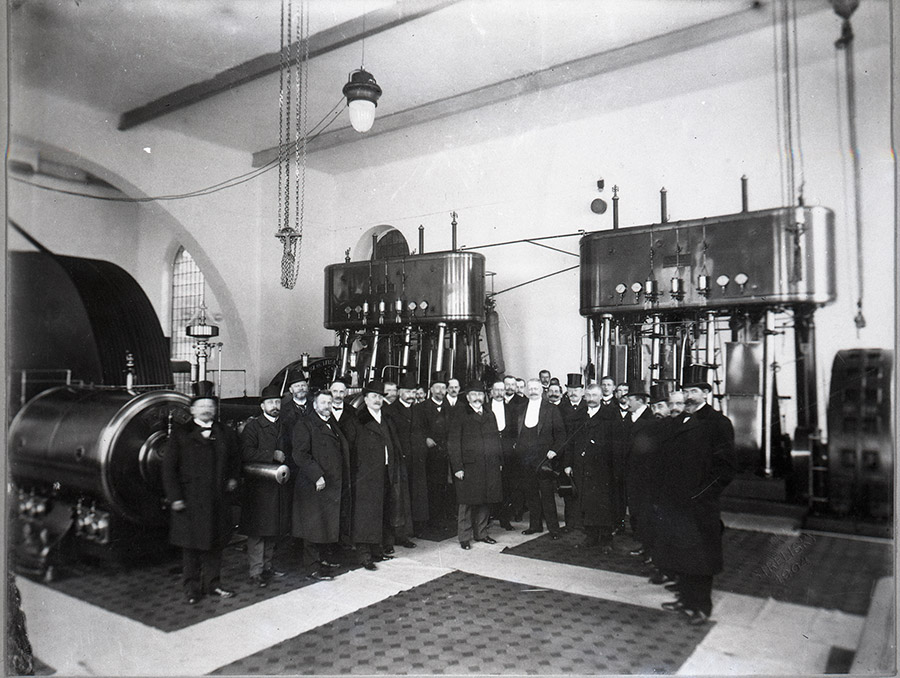

Silocentrála was the heart of the whole factory, as steam engines, main distributors, auxiliary operations, and control rooms were located there. Although the building is not officially a cultural monument, it has been preserved beyond the scope of monument protection. During the reconstruction works, the Silocentrála building also underwent a detailed renovation, and its original appearance was restored.

The original look from 1902 with a combination of coarse-grained plaster and articles of brick masonry is preserved on the Silocentrála building. It is built perpendicular to the eastern facade of Pradiareň and is joined to it by a connecting passage. It has three-storeys and an arched roof. The biggest change in Silocentrála is the replacement of the original passage connecting it to Pradiareň with a transparent glass structure with a new staircase that connects all the levels. Significant elements also include a partially suspended platform that was put in the space that was the original technological hall.

-

![Pôvodné vedenie továrne z Agnlicka v Silocentrále, 1912 / Members of the original board from England, 1912]()

Pôvodné vedenie továrne z Agnlicka v Silocentrále, 1912 / Members of the original board from England, 1912

-

![Silocentrála fungovala ako energetické centrum továrne / Silocentrála was an energetic center of the factory]()

Silocentrála fungovala ako energetické centrum továrne / Silocentrála was an energetic center of the factory

-

![Chladiarenske veže / Cooling towers]()

Chladiarenske veže / Cooling towers

Stone staircaseStone staircase

The oldest part of the Pradiareň building is a stone staircase that was built in 1902. Thanks to a sensitive reconstruction, it has been preserved along with the railing. At that time, the staircase was the only way to access the higher floors. Until 1920, it also served to transport material.

Along with the construction of Pradiareň , a central stair tower was built at the location of the central axis of the eastern facade. Its internal layout became a decisive solution in connecting the individual floors of the main building thanks to the construction of a double flight staircase. The stair treads were made of terrazzo, and the landings had a ceramic floor. The walls of the premises were covered with cement plaster, which was smoothed with felt, and white lime paint. The transport of raw cotton, the distribution of semi-finished products, and the transfer of finished materials from the individual floors to other operating parts of the thread factory were ensured by freight elevators, which were situated as an internal installation on the north and south walls of the hall.

-

![Pôvodné kamenné schodisko z roku 1902 je funkčné dodnes / The original stone staircase from 1902 is still functional today]()

Pôvodné kamenné schodisko z roku 1902 je funkčné dodnes / The original stone staircase from 1902 is still functional today

-

![Pôvodné historické schodiská boli doplnené modernými výťahmi / The original stairs were complemented by modern elevators]()

Pôvodné historické schodiská boli doplnené modernými výťahmi / The original stairs were complemented by modern elevators

The MDŽ factoryThe MDŽ factory

Women from Slovakia and abroad worked at Pradiareň, and therefore, from 1952 – 1991 the factory was called the International Women's Day Factory.

On March 8, 1952, on International Women's Day, Cvernovka and Danubius factories merged and were ceremoniously renamed the International Women's Day Factory. From the original 640 employees, the factory's staff grew to more than 2,500 employees over the course of half a century, of which up to 3/4 were women. It was the golden age of the company; the factory processed cotton from Soviet Central Asia and produced products of all kinds under the capitalist brand Squirrell. The factory reached its peak in the 1960s, and it eventually went bankrupt thirty years later when the supply of steam was cut off. On January 8, 1991, the MDŽ Factory was renamed the Bratislavská cvernová factory, a joint-stock company.

-

![Jedno z poplašných cvičení pracovníčok továrne / One of employees emergency trainings]()

Jedno z poplašných cvičení pracovníčok továrne / One of employees emergency trainings

-

![Vo fabrike pracovali aj zahraničné pracovníčky napríklad z Kuby či Vietnamu / Factory had a numerous foreign employees from Cuba or Vietnam for instance]()

Vo fabrike pracovali aj zahraničné pracovníčky napríklad z Kuby či Vietnamu / Factory had a numerous foreign employees from Cuba or Vietnam for instance

-

![Branno-športové hry pracujúcich žien v továrni / Employees sport event]()

Branno-športové hry pracujúcich žien v továrni / Employees sport event

Industrial palaceIndustrial palace

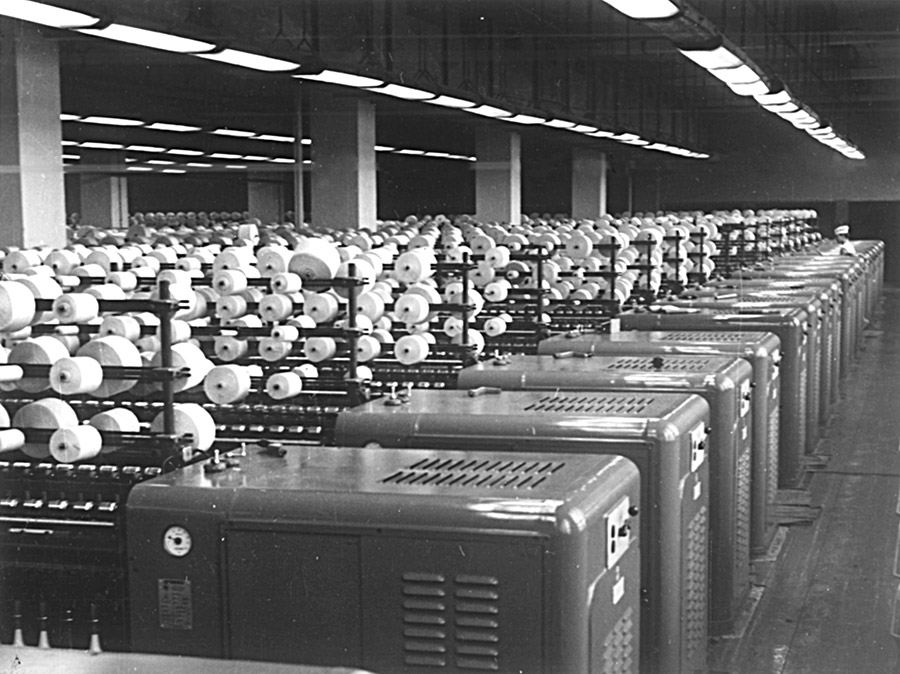

The building of Pradiareň, also called the "Industrial Palace", was the most impressive building in the entire factory. Its unique construction consists of 403 cast iron columns made in the Schlick and Waagner foundries in Budapest.

The construction system of Pradiareň was fully subordinated to the size and performance of the machines that were located in it. The construction of the building consists of cast iron columns together with rail beams, into which the vaults are built. The height of the columns is up to 5,100 mm and their diameter is 250 mm. It is a unique load-bearing structure that only occurs in Art Nouveau buildings. The characteristic features of the building, such as the façade and shapes, were already an indispensable brand of the factory at the time of the establishment of Pradiareň. In 1910 it was already the largest industrial enterprise in Bratislava. 993 people worked here, of which 640 were women. There were 22,000 spinning spindles on the machines at that time. At the threshold of the 20th century, the building represented the pinnacle of artistic and structural architecture of the period.

Cotton processingCotton processing

The first floor of Pradiareň was where cotton was brought from the ground floor by an elevator on the south side after initial processing. Subsequently, it passed through fly frames, which adjusted the thickness of the fibers.

The cotton yarn that passed through the fly frames was still raw and had not been given a metric number. In order to get it, it had to be twisted, and that’s exactly what ring spinning machines were used for. Subsequently, the yarn was sent down the line for further processing, where there were once again machines to give the yarn the necessary twists. Upon completion of these operations, the yarn was ready for tanning, which got rid of the fibrous hairs. 22,000 spinning and 20,000 thread spindles were used to produce threads and yarns. Cvernovka produced various kinds of yarns and threads, which were mostly for the domestic market, and up to 20,000 balls of yarn per year. The processing of rare cotton from Uzbekistan and Tajikistan and various colored threads ensured its leading position on the European market.

-

![]()

-

![]()

-

![]()

-

![]()

-

![Mechanická dielňa / Engineers room]()

Mechanická dielňa / Engineers room

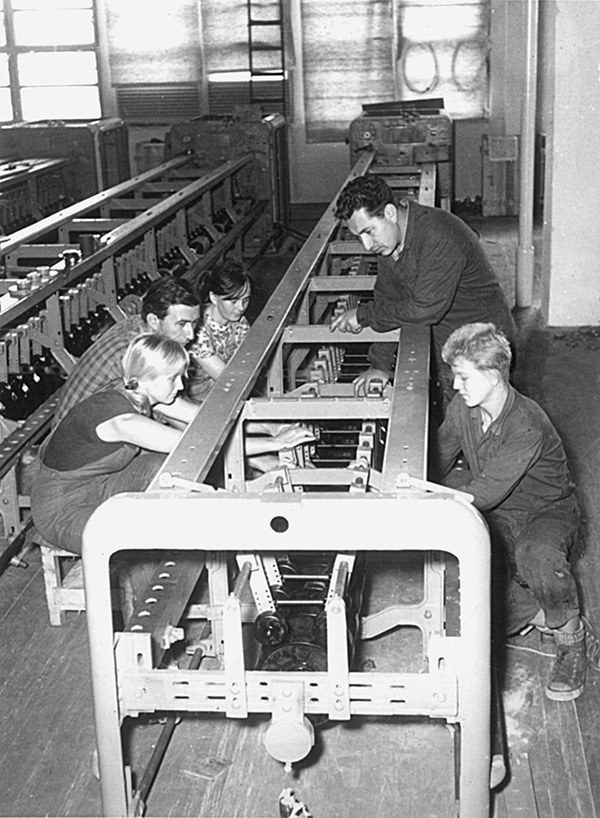

Modernization of PradiareňModernization of Pradiareň

Silocentrála was originally designed for a steam engine, which was to drive machines using gear belts. In 1902, however, a more modern, electric technology was implemented. A mezzanine was built into the original hall to take advantage of the space.

An important factor in the operation of the new technological building that impacted the layout of the building was the transport of material. The semi-finished cotton products required constant movement in both horizontal and vertical directions, and therefore in 1920, three freight elevator shafts were built into the eastern facade. On all the floors of Pradiareň there were machines powered by transmissions, which were driven by a machine in the engine room through sets of cables that were located in the middle of the building. The engine room building joined Pradiareň in this very place. The engine room was filled mainly with the most modern propulsion machines, which were initially powered by steam. There were two separate cooling towers in the yard in the immediate vicinity of the engine room. They served as cooling elements in the steam production process. The towers carried out their function until the boiler room was shut down in 1963, when the entire factory was connected to the city's electricity grid. In 1964, a modern reinforced concrete building, was built next to Pradiareň. A great expansion and modernization of Pradiareň took place in the 50s and 60s of the 20th century. In 1958, a dormitory with a capacity of 400 beds, a vocational school, and classrooms were built. Three years later, a new factory canteen, which part of the dormitory building, also began operating.

-

![Dostavba etážovej budovy - Various buildings were constructed later in 20th century]()

Dostavba etážovej budovy - Various buildings were constructed later in 20th century

-

![Dostavba etážovej budovy / Various buildings were constructed later in 20th century]()

Dostavba etážovej budovy / Various buildings were constructed later in 20th century

-

![]()

-

![]()

-

![]()

International projectInternational project

The project of the factory and its eight buildings was designed by the Imperial-Royal Construction Adviser and City Building Master from Vienna, David Valentin Junk. The construction and engineering company Pittel & Brausewetter also helped with the project.

Foreign capital and the rich experience of powerful businessmen and owners of several factories from Austria and Great Britain made the establishment of Pradiareň possible. The original owners of the factory were two companies - the Viennese company Salcher & Richter and the thread production company J. & P. Coats. The company Pittel and Brausewetter also got significantly involved in the construction of Pradiareň, as it constructed and later designed most of the original buildings. The company began experimenting with the then little-used Portland cement and built a reputation on this know-how. The structure of Pradiareň consists of 403 cast iron columns, which were made in the Schlick foundry in Budapest, together with rail beams into which the vaults were built. The factory machinery was mostly of English origin, but during the Second World War it was supplemented with spinning machines from Switzerland. Many people from third world countries with whom there were friendly relations, especially those from Cuba and Vietnam, worked at Pradiareň.

Production in PradiareňProduction in Pradiareň

Each floor had its own specific characteristics - the architectural design was always based on the layout needs of individual processes. Raw cotton was still processed on the ground floor, and the thickness of the fibers was adjusted by a machine on the first floor. On the second floor, the yarn was still raw without its metric number, which it obtained on the third floor by being twisted on ring spinning machines.

Raw cotton from various parts of the world arrived at Pradiareň in heavy bales weighing 250 kilograms that were ready for processing. The whole process of yarn production began on the ground floor, where the initial processing operations took place, such as mixing the cotton, fluffing it, winding it on a spool, and combing it. The whole production process started by loosening a bale of compressed cotton using a carousel, in which 6 bales of cotton were placed. On its sides were steel reels with sharp points that picked cotton from the bale. A strong airflow then blew the loose cotton into the pipeline to other machines. The combing process, where short and long fibers were separated, was important. Up to 20% of it were cotton noils, or in other words, production waste. After the raw cotton went through the initial operations on the ground floor, it reached the second floor thanks to an elevator on the south side. Here it passed through fly frames, which adjusted the thickness of the fibers. The yarn that emerged was still raw and did not yet have a metric number. In order to get it, it had to be twisted, which is what the ring spinning machines on this floor were used for. The fourth floor was used to complete the yarn for further processing. Here there were also machines that gave the yarn the necessary twists. Upon completion of these operations, the yarn was ready for tanning, which stripped off the hairs. The yarn was moved from Pradiareň to the dye-house building. There, it was not only dyed to the desired shade, but also refined using various technological procedures. In the beginning of the factory’s operation, it was also wound on the required type of spool there. After packing, it was sent off to various parts of the monarchy and abroad.

The main hallThe main hall

In 1943, the ceiling of the main hall with generators was rebuilt with a unique design. Under the characteristic arched roof of the Silocentrála, another working space was created.

One floor was added onto the building by Pittel & Brausewetter, and a different type of columns, ceiling, and windows were used. From the exterior, however, the building gave the impression of being consistent. The technology hall, which was the structural support for the Silocentrála area, had its ceiling overlaid with a large-span wire-reinforced concrete slab. The ceiling, suspended on a two-level riveted truss structure with an arch, defined the characteristic shape of the roof. The architecture was dominated by distinctive steel windows in the typical industrial style and architectural elements made of bricks. The technology hall was equipped with modern technology from the company Rieter.

Thread machines in Pradiareň

The largest companyThe largest company

In 1910, the thread factory was the largest industrial enterprise in Bratislava. 993 people of various nationalities worked here, of which 640 were women. On the 3rd floor, the yarn received its final twist. There were up to 22,000 spindles spinning on the machines at a time.

A number of foreigners came to the factory for training. They were citizens of countries with whom there were friendly relations, such as Cuba and Vietnam. The processing of rare cotton from Uzbekistan and Tajikistan and various colored yarns ensured its leading position on the European market. The Pradiareň produced various kinds of yarns and threads, which were mostly for the domestic market, and up to 20,000 balls of yarn per year. Thanks to one of the last Hungarian industrial laws, the Cvernová factory became the only thread factory in Hungary. At the turn of the 20th century, the Pradiareň represented the artistic and engineering peak of the industrial architectural period.

-

![Farbiareň a v pozadí chladiace veže / Coloring building with cooling towers in back]()

Farbiareň a v pozadí chladiace veže / Coloring building with cooling towers in back

-

![]()

-

![Kotolňa, 1912 / Boiler house, 1912]()

Kotolňa, 1912 / Boiler house, 1912

-

![Kotolňa, 1912 / Boiler house, 1912]()

Kotolňa, 1912 / Boiler house, 1912

-

![Kotolňa, 1912 / Boiler house, 1912]()

Kotolňa, 1912 / Boiler house, 1912

The Pradiareň superstructureThe Pradiareň superstructure

The third floor was completed after 1920. Thanks to this addition, we can consider it a superstructure. Unlike the original building with its vaulted ceilings, this floor has a flat reinforced concrete ceiling on beams and cast-iron columns with capitals.

The addition of another floor made it necessary to increase the iron construction of the lifting tower with a platform, which was situated on the northern edge of the eastern facade. The semi-finished cotton products that had been fluffed, carded, spun, twisted, and plied not only required constantly being moved horizontally on the individual floors, but also them being able to move vertically was of very high importance. In 1920, practical experience from production made it clear that there was a necessity to add freight elevators to the eastern facade. They were built in the middle and along the edges of the eastern facade as a rectangular extension where there had previously been window openings. The windows on each floor were converted into double-leaf elevator doors. The elevator engine rooms were located at the end of the extensions at the roof level by the addition of towers where the attic engine rooms were located. The older part of the attic from the 3rd building stage around the perimeter covered the low single-pitch roof. In principle, the necessary yet effective implementation of reconstructions in the 4th stage brought about the definitive solution to transport problems in the historic industrial building all the way up to present times.

Fire protection systemFire protection system

The reconstructed Art Nouveau staircase serves as an access way to one of the two preserved fire tanks. In the event of a fire, water was released from the tank above the stairs into a system of fire extinguishers located under the ceilings of the entire building. The water level in the tank could be checked on the preserved water gauge on the facade. The tank in the tower and the fire protection system are still functional.

In 1911, a second boiler room with a new tall chimney was added to the Pradiareň. The new boiler room was a simpler construction, with high coal hoppers and an interestingly designed longitudinal ventilation skylight on the ridge of the roof. Its chimney was part of one of the facades, and it formed a dominant brick part of the exterior and interior. The roof of the boiler room was made of light riveted beams and sheet metal. In the event of an explosion or fire, this construction was to provide space for reducing the shockwave and to ensure the lowest possible financial losses.